Pharma Supply Chain Transparency & Digital Asset

Blockchain transforms pharmaceutical transparency by automating track-and-trace via Hyperledger Fabric. Integrating IoT sensors, this platform eliminated supply chain visibility gaps, driving 100% counterfeit detection and a 75% reduction in compliance costs through real-time administrative efficiency

Problem Statement

Manufacturers lack a streamlined platform to track medications, verify distributor legitimacy, manage batch recalls, and monitor cold-chain compliance, increasing overall pharmaceutical supply chain risks.

Goals

Automate product tracking and stakeholder coordination.

Secure communication with immutable records and clinical updates.

Integrate IoT sensors and administrative audit tools

Enhance efficiency by blockchain smart contract workflows.

Product Overview

The Blockchain Supply Chain Platform is a unified network for stakeholders, providing everything required to manage pharmaceutical tracking and safety. Users can verify product authenticity, monitor temperature excursions, review digital health credentials, and access audit logs.

The system also offers IoT syncing, automated alerts, and recall triggers for a secure experience including immutable records and advanced data privacy. With smart contracts, real-time verification, and integration options for manufacturers, the platform ensures every shipment is compliant and effortless. Whether it’s managing batch recalls, navigating regulatory audits, or enjoying seamless data portability, this blockchain is built to maximize patient safety and transparency.

Responsibility

Tools

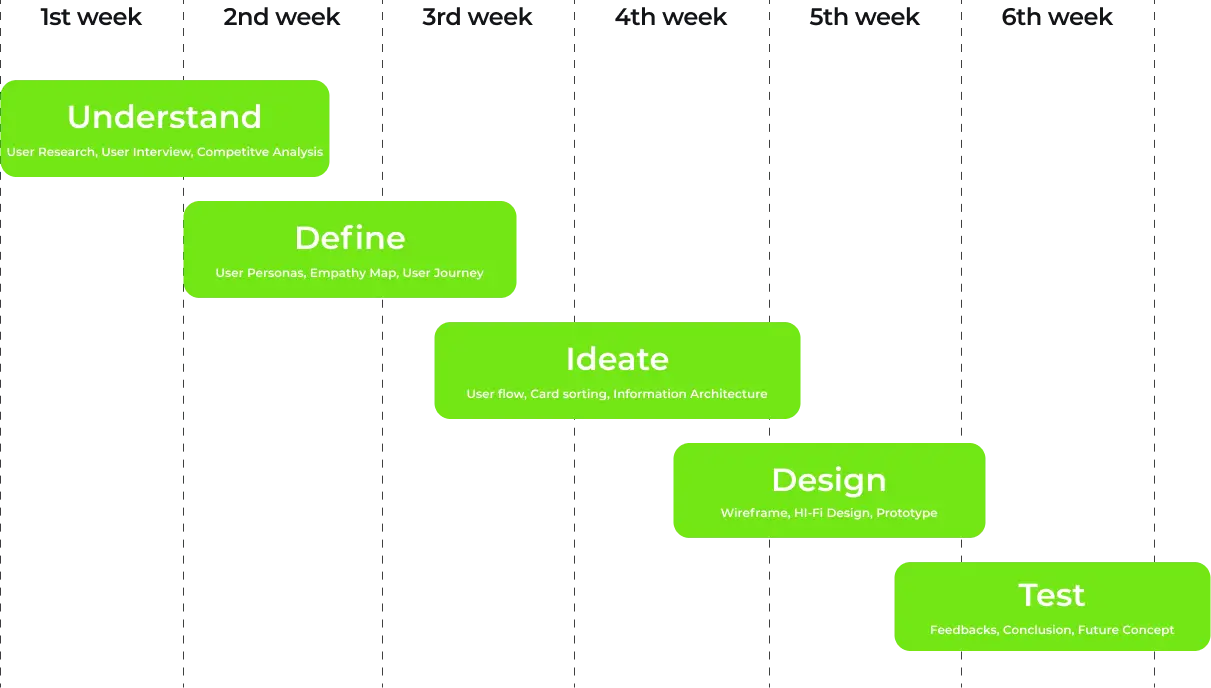

Design Process

The design process follows a structured approach: Understand user needs, define key features, ideate solutions, design the interface, and test for usability and performance. This ensures a user-centered, functional, and engaging app experience.

Understand

User Research

User Interview

Competitive Analysis

Define

User Personas

Empathy Map

User Journey

Ideate

Information Architecture

Design

Wireframe

Hi-FI Design

Prototype

Test

Feedbacks

Conclusion

Future Concept

Design Timeline

Target Audience

Patients requiring authentic medications and portable health credentials.

Healthcare providers seeking supply chain transparency and compliance efficiency.

Stakeholders interested in pharmaceutical tracking, cold-chain safety, and regulatory audit readiness.

Industry participants looking for a decentralized and secure platform for pharmaceutical logistics.

User Research

User research involved audits and interviews with pharmaceutical manufacturers and distributors, revealing a need for a transparent platform. Users prioritized product authenticity, cold-chain visibility, and rapid recall execution. Automated triggers and real-time monitoring were key desires for enhancing supply chain integrity.

Competitive Analysis

Current supply chain tools lack a comprehensive platform integrating blockchain, real-time IoT sensors, and immutable records. Competitors offer limited tracking features, missing the opportunity for instant counterfeit detection, automated audit reporting, and a seamless regulatory experience.

Service Name

ERP System

Track-and-Trace

Manual Ledger

Blockchain Hub

Service Info

Legacy enterprise resource planning

Standard medication tracking

Manual paper-based records

Permissioned blockchain network

Prediction

Syncing

Alerts

Management

AI Assistant

Factory Info

Automation

Key Features

Blockchain-powered ledger provides 24/7 immutable tracking support and personalized data ownership.

Direct IoT syncing increases operational speed with real-time readings and instant alerts.

Allows stakeholders to access medication history and seamless updates on product authenticity.

Smart contracts unlock administrative savings and rapid recalls, reducing manual verification tasks.

Quantitative Research

The Blockchain Supply Chain & Digital Asset project aims to provide a secure and transparent experience for healthcare stakeholders and patients. Our quantitative research involved analyzing pharmaceutical logistics data, focusing on functionalities like track-and-trace, cold-chain monitoring, audit automation, and patient data portability.

Screeners

Stakeholders seeking a permissioned blockchain interface for real-time pharmaceutical tracking activities.

- Manufacturers interested in managing shipment pipelines and subscribing for automated temperature alerts.

- Distributors looking for verified product authenticity templates and global supply chain availability.

- Regulators who value instant audit response times and automated compliance reporting support.

- Patients aged 18-80 regularly engaging with digital health platforms for prescriptions and records.

Key Performance (Baseline vs. Target)

2-4 Weeks to <48 Hours

Audit Readiness Time: Time from initial request to a ready-to-audit environment reduced via automation.

2-4 Weeks to <4 Hours

Recall Execution Lead: Drastic reduction in the time required for contaminated doses to move from detection to quarantine.

$300M to $50M

Compliance Spend Reduction: Percentage of pharma budget spent on routine manual reporting and audits versus strategic safety.

Monthly to Instant

Verification Frequency: Shifted from manual batch reconciliation to a real-time production unit verification cadence.

24+ Hours to <15 Mins

Time to Remediate Excursion: Time from deviation detection to resolution through automated sensor monitoring and alerts.

7.3x ROI

Overall Operational Savings: Reduction in total supply chain spend through anti-counterfeiting, automation, and efficiency.

1. Fragmented Supply Chain Systems

Stakeholders currently have to rely on multiple channels to access drug availability, audit logs, temperature records, and shipment updates. This fragmented access to information creates confusion, delays, and unnecessary time spent searching for accurate pharmaceutical supply chain guidance.

2. Lack of Real-time Visibility

Existing tracking methods do not provide tailored information based on individual batch history, cold-chain needs, or urgent recall requirements. Important updates, alerts, or storage instructions are often generic and not customized to each shipment’s specific medical situation.

3. Absence of Patient Control

There is a lack of structured digital tools or automated systems that recognize patient urgency. Patients want clearer advantages from manufacturer participation, such as exclusive health resources, 24/7 authenticity access, or digital record services that add tangible convenience.

User Persona: David Chen

Name:

Marcus Chen

Age:

42

EDUCATION:

Senior Cloud Architect

Job:

Lead Platform Engineer

Location:

Seattle, USA

HOBBIES:

Reviewing system breakthroughs, family time, travel

Bio

David is a regional supply chain director and an essential member of a global distribution network committed to operational excellence. He manages high-volume shipments across various hubs and facilities, necessitating that he stay informed regarding serialization laws, storage protocols, and inventory updates.

Personality

Responsible

Analytical

Compliance-driven

Efficient

Pain Points

Difficulty staying updated with manual reconciliation and fragmented distribution reports.

Struggles to verify product legitimacy across different unauthorized market operators.

Desires more direct, transparent, and faster temperature alerts from IoT sensor networks.

Goal

Maintain real-time awareness of cold-chain compliance and professional safety standards.

Improve audit readiness through enhanced blockchain transparency and immutable data clarity.

Rely on automated track-and-trace for distribution representation and inventory protection.

User Persona: Sarah Jenkins

Name:

Sarah Jenkins

Age:

48

EDUCATION:

Global Logistics Management

Job:

Senior Logistics Manager

Location:

London, UK

HOBBIES:

Technical writing, sailing with family, volunteering

Bio

Sarah is a senior logistics manager at a major pharmaceutical firm committed to global drug safety. She oversees complex distribution across 60+ countries, requiring her to stay informed about unit tracking, cold-chain compliance, and global regulatory updates.

Personality

Organized

Detail-oriented

Safety-focused

Strategic

Pain Points

Difficulty tracking real-time visibility across 40+ global distribution hubs.

Struggles to verify product legitimacy across different unauthorized market operators.

Struggles to access consolidated temperature data across different shipping routes.

Goal

Achieve 100% real-time tracking from manufacture to the final patient.

Improve recall efficiency through automated blockchain-driven smart contract triggers.

Rely on digital credentials for seamless product authentication and patient protection.

User Journey Map

Persona: Carlos Martínez (Senior Risk Operations Manager)

Actions

Verification

Collaboration

Compliance

Optimization

Task List

Checks product authenticity in the region.

Shares logistics data with local hospitals.

Prepares documentation for FDA/EU audits.

Analyzes ROI and supply chain efficiency.

Feeling

"Is this batch verified for safe distribution?"

"Everyone needs access to the same ledger."

"The audit trail must be 100% accurate."

"We’ve reduced compliance costs significantly."

Thoughts

Cautious about unauthorized market units.

Collaborative and ready to share data.

Weeks spent on manual reconciliations.

High overhead for routine safety reporting.

Improvement Opportunities

High volume of counterfeit pharmaceutical units.

Siloed data preventing patient portability.

Use smart contracts for automated auditing.

Scale the pilot to all global product lines.

Actions : Action 1

Actions

Checks product authenticity in the region.

Thinking

"Is this batch verified for safe distribution?"

Feeling

Cautious about unauthorized market units.

Pain Point

High volume of counterfeit pharmaceutical units.

Opportunity

QR codes for instant unit authentication.

Actions : Action 2

Actions

Track urgent repair bookings

Thinking

Satisfied with live updates

Feeling

It’s great to see live machine queue updates.

Pain Point

Provide an asset filter for schedules Personalize plant flows for staff

Opportunity

QR codes for instant unit authentication.

Actions : Action 3

Actions

Checks product authenticity in the region.

Thinking

Cautious about unauthorized market units.

Feeling

Cautious about unauthorized market units.

Pain Point

High volume of counterfeit pharmaceutical units.

Opportunity

QR codes for instant unit authentication.

Actions : Action 4

Actions

"Is this batch verified for safe distribution?"

Thinking

"Is this batch verified for safe distribution?"

Feeling

Cautious about unauthorized market units.

Pain Point

High volume of counterfeit pharmaceutical units.

Opportunity

QR codes for instant unit authentication.

User Journey Map

Persona: Sarah Jenkins (Cloud Operations Director)

Actions

Verification

Collaboration

Compliance

Optimization

Task List

Conducts audits on onboarding processes.

How can we enhance team synergy?

Ensures all products meet regulatory standards.

Implements continuous improvement strategies.

Feeling

Are we capturing all necessary data points?

How can we enhance team synergy?

What are the most recent compliance updates?

How can we streamline our operations?

Thoughts

Cautiously optimistic about the results.

Energized by collaborative efforts.

Anxious about upcoming inspections.

Motivated to maximize efficiency.

Improvement Opportunities

Inconsistent verification protocols.

Limited engagement from some partners.

Complicated compliance documentation.

Inefficiencies in resource allocation.

Actions : Action 1

Actions

Conducts audits on onboarding processes.

Thinking

Are we capturing all necessary data points?

Feeling

Cautiously optimistic about the results.

Pain Point

Inconsistent verification protocols.

Actions : Action 2

Actions

Facilitates regular stakeholder meetings.

Thinking

How can we enhance team synergy?

Feeling

Energized by collaborative efforts.

Pain Point

Limited engagement from some partners.

Actions : Action 3

Task List

Access unit repair records

Feeling

Happy about data accuracy

Thoughts

This automation will be perfect for my staff!

Improvement Opportunities

More integrations for industrial items Introduce industrial resource packs

Actions : Action 4

Task List

Subscribe to AI health alerts

Feeling

Relieved to manage technical content.

Thoughts

The AI should help me stay organized.

Improvement Opportunities

Simplify automated management Enhance plant loyalty benefits

Key Takeaways

The Blockchain Supply Chain Platform is engineered to centralize pharmaceutical operations by offering real-time tracking, cold-chain monitoring, and recall automation within one ecosystem. Our research highlights the necessity for integrated transparency, addressing the frustrations manufacturers face with current manual-based solutions. Features like the IoT syncing, smart contracts, and immutable ledgers add value to the business journey. Results revealed 100% counterfeit detection, while a 75% reduction was achieved for compliance costs and automated audit updates. The platform caters to diverse personas—logistics managers, supply directors, and regulatory stakeholders—ensuring safety and engagement. This project redefines how medical institutions connect with their global distribution networks, enhancing both security and loyalty.