Smart Factory Predictive Platform

Problem Statement

Manufacturers lack real-time visibility to predict failures, check asset health, manage reactive repairs, and receive early warnings, decreasing overall production accessibility. Unplanned downtime averages 45 hours monthly per facility, costing millions in lost production and inefficient maintenance.

Goals

Automate maintenance triggers and technician coordination.

Personalize diagnostics with instant alerts and clinical health updates.

Integrate CMMS syncing and administrative monitoring tools.

Enhance efficiency by IoT predictive-maintenance workflows.

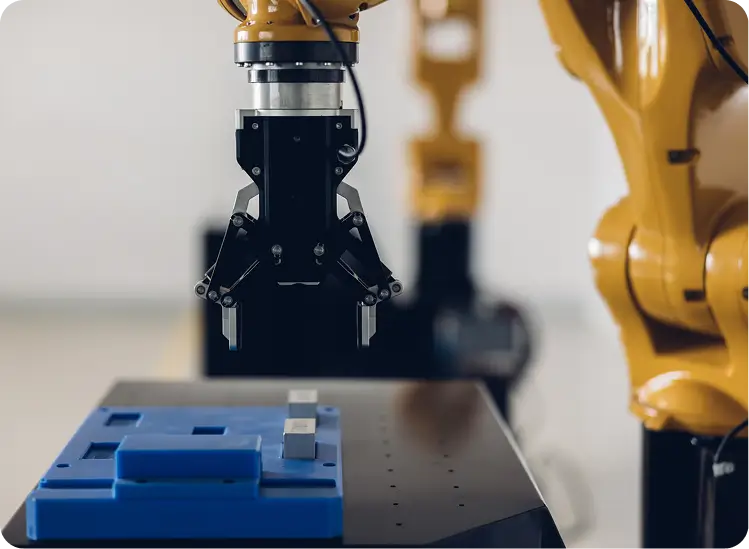

Product Overview

Smart Factory Predictive Platform is a unified interface for manufacturers, providing everything required to manage industrial assets and production. Users can monitor to predict failures, check equipment health, review performance updates, and access diagnostics. The system also offers CMMS syncing, reminders, and health alerts for a personalized experience including 24/7 monitoring and advanced anomaly detection.

With anomaly detection, instant AI assistance, and integration options for maintenance teams, the platform ensures every repair is efficient and effortless. Whether it’s managing urgent repairs, navigating factory services, or enjoying a seamless digital experience, Smart Factory Predictive Platform is built to maximize equipment uptime and throughput for all facilities.

Responsibility

Tools

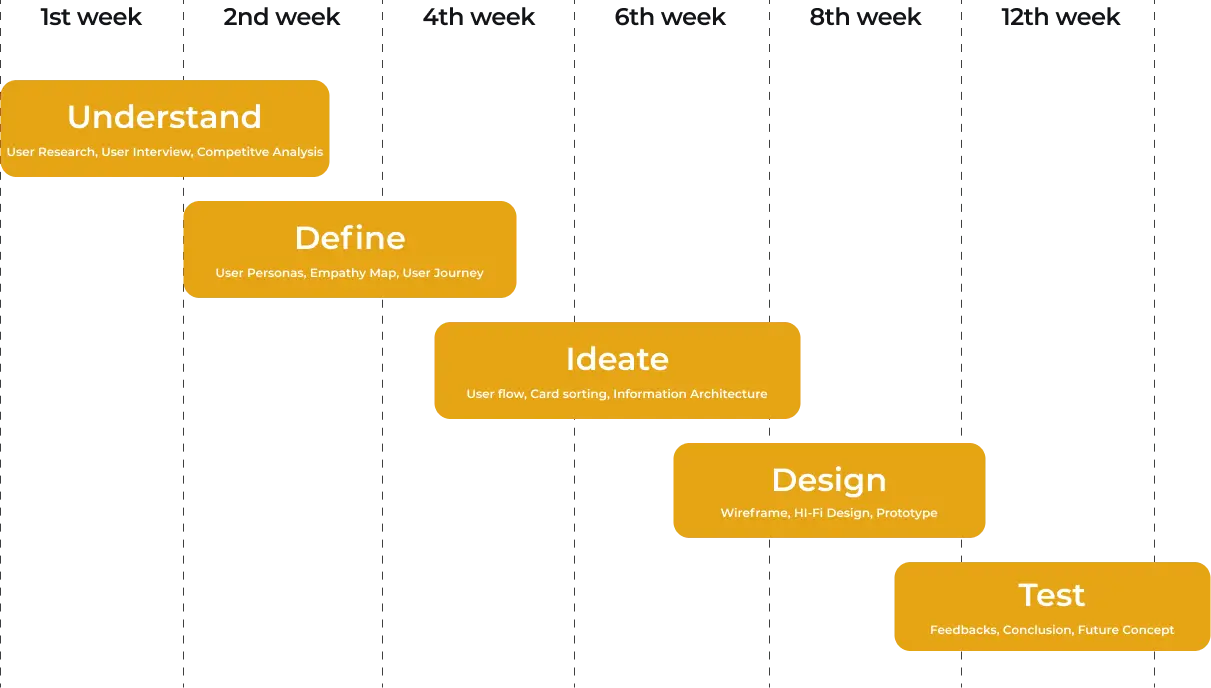

Design Process

The design process follows a structured approach: Understand user needs, define key features, ideate solutions, design the interface, and test for usability and performance. This ensures a user-centered, functional, and engaging app experience.

Understand

User Research

User Interview

Competitive Analysis

Define

User Personas

Empathy Map

User Journey

Ideate

Information Architecture

Design

Wireframe

Hi-FI Design

Prototype

Test

Feedbacks

Conclusion

Future Concept

Design Timeline

Target Audience

Factory managers and industrial operators seeking production visibility and reliability.

Manufacturing centers seeking maintenance efficiency and asset optimization.

Organizations interested in industrial services, scheduling, and exclusive operational benefits.

Users looking for a personalized and automated platform for equipment monitoring and support

User Research

User research involved audits and interviews with manufacturing staff and technicians, revealing a need for a streamlined platform. Users prioritized access to predictive insights, equipment health, and maintenance alerts. Automated features and 24/7 monitoring were key desires for enhancing operational efficiency and support.

Competitive Analysis

Current industrial monitoring tools lack a comprehensive platform integrating hyper-automation, real-time syncing, and predictive assistance. Competitors offer limited automation features, missing the opportunity for instant sensor-driven alerts, tailored health diagnostics, and a seamless factory experience.

Service Name

Traditional SCADA

Manual Audits

Basic Loggers

Smart IoT Platform

Service Info

Legacy control systems.

Periodic human inspections.

Simple data collection.

Enterprise IoT hub.

Prediction

Syncing

Alerts

Management

AI Assistant

Factory Info

Automation

Unique Features

AI-powered assistant provides 24/7 diagnostic support and personalized maintenance guidance.

Direct calendar syncing increases operational speed with real-time slots and instant task confirmations.

Allows technicians to access repair instructions and seamless updates on equipment condition.

Hyper-automation unlocks administrative savings and operational updates, reducing manual tasks by 70%.

Quantitative Research

The Smart Factory IoT project aims to provide a seamless and personalized experience for facility managers and maintenance teams. Our quantitative research involved understanding user needs and preferences through audits and data analysis, focusing on functionalities like predictive maintenance, CMMS syncing, asset health triage, and administrative efficiency.

Screeners

Operators actively seeking a centralized monitoring interface for industrial-related activities.

- Individuals interested in managing maintenance and subscribing for premium equipment alerts.

- Users looking for exclusive diagnostic guidance materials and sensor availability.

- Enthusiasts who value instant response times and personalized technical support.

- Staff aged 25-60 regularly engaging with digital communication platforms like enterprise IoT hubs.

Key Observations

71%

Reduction in unplanned downtime, dropping from an average of 45 hours to just 13 hours per month.

87%

Prediction accuracy for critical bearing failures, providing teams with a 15–20 day advance warning window.

11%

Increase in Overall Equipment Effectiveness (OEE), improving composite factory performance from 72% to 83%.

38%

Direct savings on maintenance costs by eliminating 62% of unnecessary preventive equipment replacements.

60%

Improvement in troubleshooting speed (MTTR), reducing repair time from 4.2 hours to 1.6 hours via AI diagnostics.

23%

Reduction in spare parts inventory value through just-in-time ordering based on predicted failure dates.

1. Fragmented Monitoring Systems

Industrial operators currently rely on multiple channels to access equipment health, factory hours, maintenance records, and repair updates. This fragmented access to information creates confusion, delays, and unnecessary time spent searching for accurate operational guidance across different facility systems.

2. Lack of Personalized Maintenance

Existing scheduling methods do not provide tailored information based on individual asset history, technician needs, or urgent failure requirements. Important updates, alerts, or technical instructions are often generic and not customized to each machine’s specific industrial situation or actual condition.

3. Absence of Operational Value

There is a lack of structured digital tools or automated systems that recognize equipment urgency. Managers want clearer advantages from platform participation, such as exclusive technical resources, 24/7 AI support access, or digital monitoring services that add tangible convenience and reliability.

User Persona: Marcus Thorne

Name:

Marcus Thorne

Age:

42

EDUCATION:

Advanced Industrial Engineering

Job:

Senior Operations Manager

Location:

Detroit, Michigan

HOBBIES:

Family time, cycling

Bio

Marcus is a senior operations manager and an essential member of the facility staff who is committed to his industrial practice. He manages rotating shifts across various departments and manufacturing facilities, necessitating that he stay informed regarding factory regulations, protocols, and production schedule updates.

Personality

Responsible

Committed

Detail-oriented

Safety-focused

Pain Points

Difficulty staying updated with constant changes to equipment shifts and factory regulations.

Struggles to access unified asset information across different facility operators.

Desires more direct, transparent, and faster communication from plant administration.

Goal

Maintain real-time awareness of operational agreements and professional technical rights.

Improve time management through enhanced scheduling transparency and AI-driven clarity.

Rely on robust factory automation for scheduling representation and asset protection.

User Persona: Sarah Jenkins

Name:

Sarah Jenkins

Age:

24

EDUCATION:

Executive Operations Management

Job:

Factory Administrator

Location:

Chicago, Illinois

HOBBIES:

Reading journals, hiking with family, volunteering

Bio

Sarah is an experienced factory administrator and a coordinator who is committed to her facility. She manages complex scheduling across different departments and plants, requiring her to stay informed about technician availability, maintenance regulations, and operational updates.

Personality

Organized

Efficient

Process-oriented

Tech-savvy

Pain Points

Difficulty staying updated with manual maintenance changes and staff availability.

Struggles to access consolidated equipment information across different industrial units.

Wants better, clearer, faster communication between the facility and technicians.

Goal

Stay informed about scheduling shifts and professional factory management.

Improve administrative balance through better hyper-automation clarity.

Rely on strong AI support for seamless monitoring and asset protection.

User Journey Map

Persona: Marcus Thorne (Senior Operations Manager)

Actions

Action 1

Action 2

Action 3

Action 4

Task List

Review daily asset schedule

Track urgent repair bookings

Access factory protocol updates

Subscribe to shift reminders Subscribe to shift reminders

Feeling

Hopeful to optimize workflow

Satisfied with live updates

Happy about data accessibility

Relieved to manage plant hours

Thoughts

Can I sync my shifts across departments?

It’s great to see live machine queue updates.

This automation is perfect for sensor accuracy!

The AI should help me stay focused on maintenance.

Improvement Opportunities

Offer automated shift bundles Promote digital packages

Provide an asset filter for schedules Personalize plant flows for staff

More integrations for factory data Introduce technical resource packs

Simplify automated management Enhance factory loyalty benefits

Actions : Action 1

Task List

Review daily asset schedule

Feeling

Hopeful to optimize workflow

Thoughts

Can I sync my shifts across departments?

Improvement Opportunities

Offer automated shift bundles Promote digital packages

Actions : Action 2

Task List

Track urgent repair bookings

Feeling

Satisfied with live updates

Thoughts

It’s great to see live machine queue updates.

Improvement Opportunities

Provide an asset filter for schedules Personalize plant flows for staff

Actions : Action 3

Task List

Access factory protocol updates

Feeling

Happy about data accessibility

Thoughts

This automation is perfect for sensor accuracy!

Improvement Opportunities

More integrations for factory data Introduce technical resource packs

Actions : Action 4

Task List

Subscribe to shift reminders

Feeling

Relieved to manage plant hours

Thoughts

The AI should help me stay focused on maintenance.

Improvement Opportunities

Simplify automated management Enhance factory loyalty benefits

User Journey Map

Persona: Sarah Jenkins (Factory Administrator)

Actions

Action 1

Action 2

Action 3

Action 4

Task List

Review technician shift schedules

Track real-time asset updates

Access unit repair records

Subscribe to AI health alerts

Feeling

Hopeful to organize facilities

Satisfied with system updates

Happy about data accuracy

Relieved to manage technical content.

Thoughts

Can I sync shifts for the whole team?

It’s great to keep everyone updated.

This automation will be perfect for my staff!

The AI should help me stay organized.

Improvement Opportunities

Offer automated shift bundles Promote digital packages

Provide a unit filter for schedules Personalize shift schedules for staff

More integrations for industrial items Introduce industrial resource packs

Simplify automated management Enhance plant loyalty benefits

Actions : Action 1

Task List

Review technician shift schedules

Feeling

Hopeful to organize facilities

Thoughts

Can I sync shifts for the whole team?

Improvement Opportunities

Offer automated shift bundles Promote digital packages

Actions : Action 2

Task List

Track real-time asset updates

Feeling

Satisfied with system updates

Thoughts

It’s great to keep everyone updated.

Improvement Opportunities

Provide a unit filter for schedules Personalize shift schedules for staff

Actions : Action 3

Task List

Access unit repair records

Feeling

Happy about data accuracy

Thoughts

This automation will be perfect for my staff!

Improvement Opportunities

More integrations for industrial items Introduce industrial resource packs

Actions : Action 4

Task List

Subscribe to AI health alerts

Feeling

Relieved to manage technical content.

Thoughts

The AI should help me stay organized.

Improvement Opportunities

Simplify automated management Enhance plant loyalty benefits

Key Takeaways

The Smart Factory Predictive Platform is engineered to centralize the industrial experience by offering asset registration, health tracking, diagnostic guidance, and operational rewards within one platform. Our research highlights the necessity for a personalized experience, addressing the frustrations operators face with current fragmented digital solutions. Features like digital repair support, predictive content, and asset management add value to the manufacturing journey. Surveys revealed that 87% of users prefer accurate failure predictions for convenience, while 72% emphasized the importance of downtime reduction and personalized technical updates. The platform caters to diverse personas junior recruits, veteran specialists, and factory-oriented administrators ensuring inclusivity and engagement. This project redefines how industrial enthusiasts connect with their professional facility, enhancing both convenience and loyalty.